The type of packing products used is one of the most defining aspects of any business. The quality of your products is important, and so is the packaging application.

The right packaging can attract more customers; Poor packaging puts your business at risk of losing customers.

Are you looking for plastic bag suppliers that suit your packaging applications? Does your business need versatile and cost-effective bags for packing products?

In this article, HM Export will send you how to determine the right plastic bag that suits your business requirements.

Consider The Size and Thickness of Your Products

Size is one of the most important factors to consider when choosing a suitable plastic bag. Before making a decision, you want to measure your products and get the dimensions for length and width.

Consider the overall size and volume of the product that you want to fit. The weight and size of the product will determine which plastic bag you should invest in.

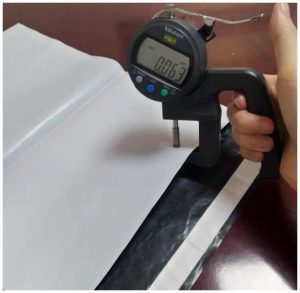

The thickness of the bag is also a factor that determines the strength and aesthetics of the bag. A bag that is too thin will not meet the requirements for strength, a bag that is too thick will be costly.

If you don’t know

how to calculate the dimension and volume of your product, reach out to HM now for instructions on the size and thickness that best suits your requirements and each market.

With our experience in manufacturing and exporting, we will advise you on the model that suits your requirements

Consider the Poly Bag Materials

Poly or plastic bags vary in their physical and chemical properties, such as durability, density, strength, thickness, and resistance.

You need to understand the different forms of plastics before choosing a suitable plastic bag for your product packaging.

The best packaging material depends on the product to be packed . Polyethylene (PE) is a strand of linked ethylene hydrocarbons, which may be highly branched, highly linear, or somewhere in between.

The degree of branching gives rise to several primary varieties of PE, including LDPE, HDPE, and LLDPE.

a.Low-Density Polyethylene (LDPE)

LDPE comprises branching chains of various lengths. As a result of the loose molecular structure of LDPE, an ideal ductile plastic for crafting film wraps and grocery bags is created.

The major drawback of LDPE is its low tensile strength, which reduces its durability. This makes LDPE bags prone to stretching or tearing.

LDPE Uses: LDPE bags find applications for grocery bags and single-use production. They can be used for FDA-compliant, food-safe varieties.

b. High-Density Polyethylene (HDPE)

HDPE sometimes has a single ethyl branch per 100 molecule chains, making it the most linear ethylene polymer.

As a result of this unique property, HDPE is the densest and strongest PE. Like LDPE, HDPE can form stiff and moisture-resistant poly bags, making them ideal for manufacturing pipes, heavy materials, and other solid components.

HDPE Uses: Since HDPE is highly durable than other PEs, HDPE finds its application in packaging cement, fertilizers, animal feed, grains, and bulky industrial components.

c. Linear Low-Density Polyethylene (LLDPE)

LLDPE is slightly denser than LDPE, but it is more durable and offers better tensile strength than LDPE and HDPE.

This is because LLDPE is composed of molecules with shorter branches, which allows for a more uniform linear structure.

LLDPE Uses: As a result of its properties, LLDPE bags are available in light to heavy gauges. If you are packaging foods, consumer goods, and other lightweight industrial products, then LLDPE is ideal for you.

Ideally, your plastic bag should be:

- Easy-to-use: Plastic bags are easier and quicker to open up, pack and reuse.

- Durable: The plastic bag should be durable and resistant to tearing, stretching or breaking.

- Economical: Plastic bags are more economical than other paper bags. Their prices are economical if purchased in bulk.

- Customizing designs: Your choice of plastic bags should come with customization like imprinting your business name and logo onto the front.

- Quality print: Make sure you choose the plastic bag that will retain prints. Avoid plastic bags whose print tends to clear off pretty fast – they are of inferior quality.

Final Thoughts

The primary purpose of packaging is to ensure that your product reaches its final destination without any damage. As a plastic company in Malaysia, we emphasize the importance of using plastic bags from a reliable plastic bag manufacturer to ensure that your products reach customers in excellent condition.

Poly bags come in different shapes and materials and they are not all of similar quality. Some are large and dense, others are light and durable.

To accommodate your packaging needs, it is important to consider the optimal material and the size of your product to get the desired results.

Please contact us immediately for useful advice.

We appreciate the opportunity to work with all of you.