Global demand for plastic resins is expected to increase in the period 2024-2025, opening up opportunities for businesses producing and exporting Vietnamese plastic resins. Below we would like to summarize some advantages businesses need to grasp and take advantage of to develop their business activities:

Demand for plastic resins increases, increasing export advantages

ICIS forecasts show that global plastic resin demand is expected to increase by about 4.4%/year in the period 2023-2025. Global demand for plastic resins largely comes from the Chinese market, the Asia-Pacific region and Europe. In the coming period, the growth in demand for plastic resins will depend largely on growth from the Chinese market, in addition to other developing Asian countries. China is the world’s largest plastic resin consumption market and the main driving force of the global plastic resin market. In developing countries in the Asia-Pacific region, including Vietnam, the demand for plastic resins will likely continue to increase.

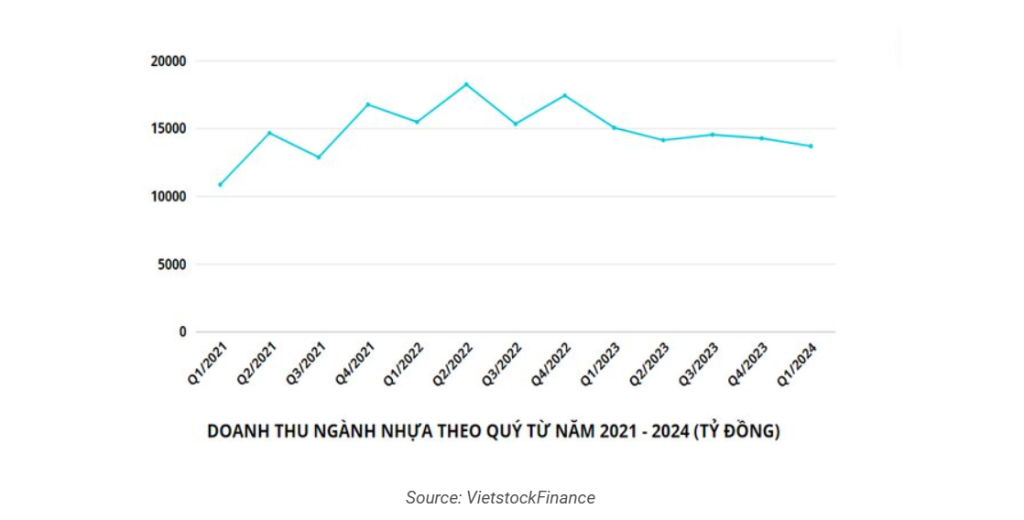

In Vietnam, compared to other long-standing industries (such as mechanical engineering, electricity – electronics, chemicals, textiles…) the plastic industry is still quite new. However, in recent years, Vietnam’s plastic industry has developed strongly, with an annual increase of 16% – 18%/year (only behind the telecommunications and textile industries). In particular, there are products whose growth rate is nearly 100%. With rapid development, the plastic industry is considered a dynamic industry in the Vietnamese economy.

Development trends of packaging plastic

Consumer income and spending levels will directly affect the demand for output products of packaging plastic. Vietnam currently has about 14,000 packaging businesses. Of which, plastic packaging accounts for about 9,200 businesses. We estimate that the growth of the plastic packaging segment in 2023 in Vietnam will lie in the growth of spending on food and non-alcoholic beverages.

The plastic packaging trend is expected to become very popular because this is a minimalist trend and maximizes reuse of used plastic materials on the market.

Besides, plastic packaging will be divided into 2 main groups. First, plastic packaging is produced from the PE plastic group. This is an outstanding material with 3 characteristics, specifically as follows: waterproof, non-electrical and non-thermal. In particular, the heat tolerance of the material reaches nearly 230 degrees Celsius.

The second material line for producing plastic packaging products is the PP plastic group. Polypropylene plastic is a polymer material that is highly appreciated for its mechanical characteristics. In addition, packaging made from PP material has very good durability because of its heat resistance from 130 degrees Celsius – 170 degrees Celsius, long-term oxidation resistance as well as water and gas resistance. Therefore, plastic packaging will be very easy to apply in daily life and the production cost is not too expensive, this has met the criteria of environmental protection, developing a green economy and improving the environment. The importance of plastic products.

Introduction to HM Export

HM Export is currently a company operating in the field of plastics and plastic packaging production, we grasp the trends and promptly provide optimal, environmentally friendly material solutions, contributing to increasing the competitive advantage for businesses.

Coming to HM Export LTD, you will be assured of competitive prices, high quality and the best customer care service.

Do not hesitate to contact us, our team will serve you with our most enthusiasm.